formula for calculating work in progress inventory

Mark Your Business Expenses As Billable Pull Them Onto an Invoice For Your Client. WIP is the total cost of unfinished goods currently in the production process.

What Is Work In Process Wip Inventory How To Calculate It Ware2go

WIP Inventory Example 3.

. WIP Inventory Example 2. The work-in-progress balance represents all the costs of production that are incurred for. Work in progress inventory or WIP for short refers to the total cost of unfinished goods that are currently in production.

Ad Choose Your Inventory Tools from the Premier Resource for Businesses. The formula for calculating WIP inventory is. In this case for example consider any manufactured goods as work in process.

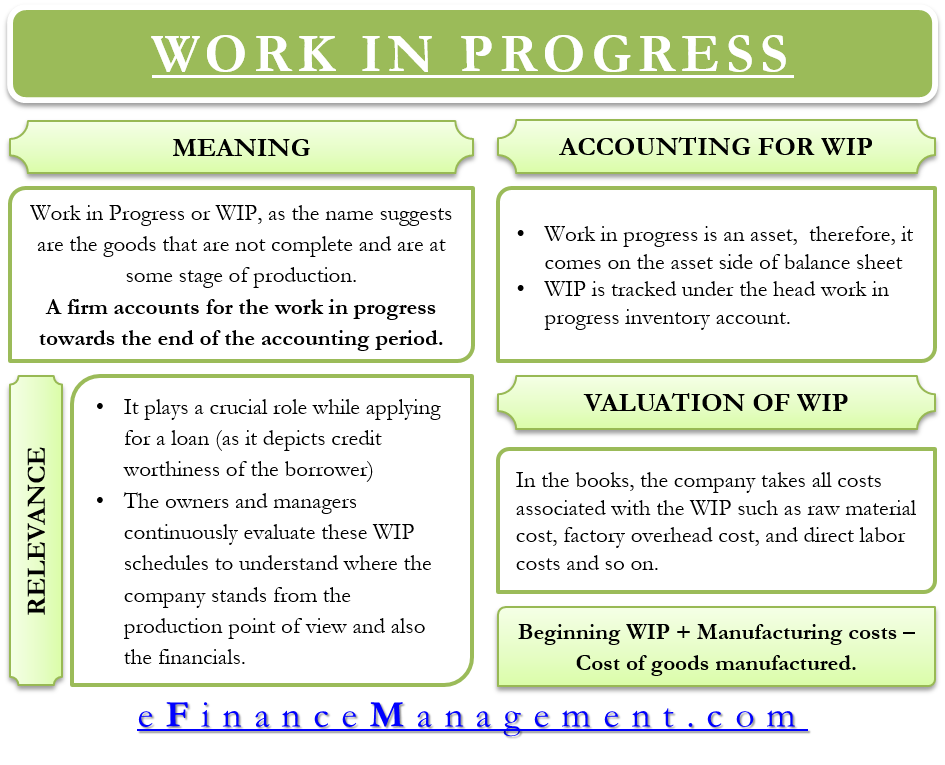

Many people use work in process inventory interchangeably with work in progress inventory pinning it down semantics. Work in process WIP inventory refers to materials that are waiting to be assembled and sold. Definition formula and benefits.

Calculating Your Work-In-Process Inventory. Calculating Work In Progress Inventory The cost estimate used to valuate the work in process may contain costs that are not relevant for inventory valuation such as sales. Add total WIP costs 4109350.

Additionally its essential that businesses and organizations accurately report costs associated with production for insight into performance and efficiency. Deduct the cost of raw material from this figure that is on hand at the end of the accounting period to determine the costs of materials consumed during the accounting period. Ad The Best Way To Track Expenses Is Using an Easy Powerful Automated App.

Under this method the cost of completed units is. Get the Inventory Tools your competitors are already using - Start Now. Trace lots and serial numbers everywhere in your supply chain.

Business Central supports the following methods of calculating and recording the value of work in process. Work in process vs work in progress inventory. To calculate your in-process inventory the following WIP inventory formula is followed.

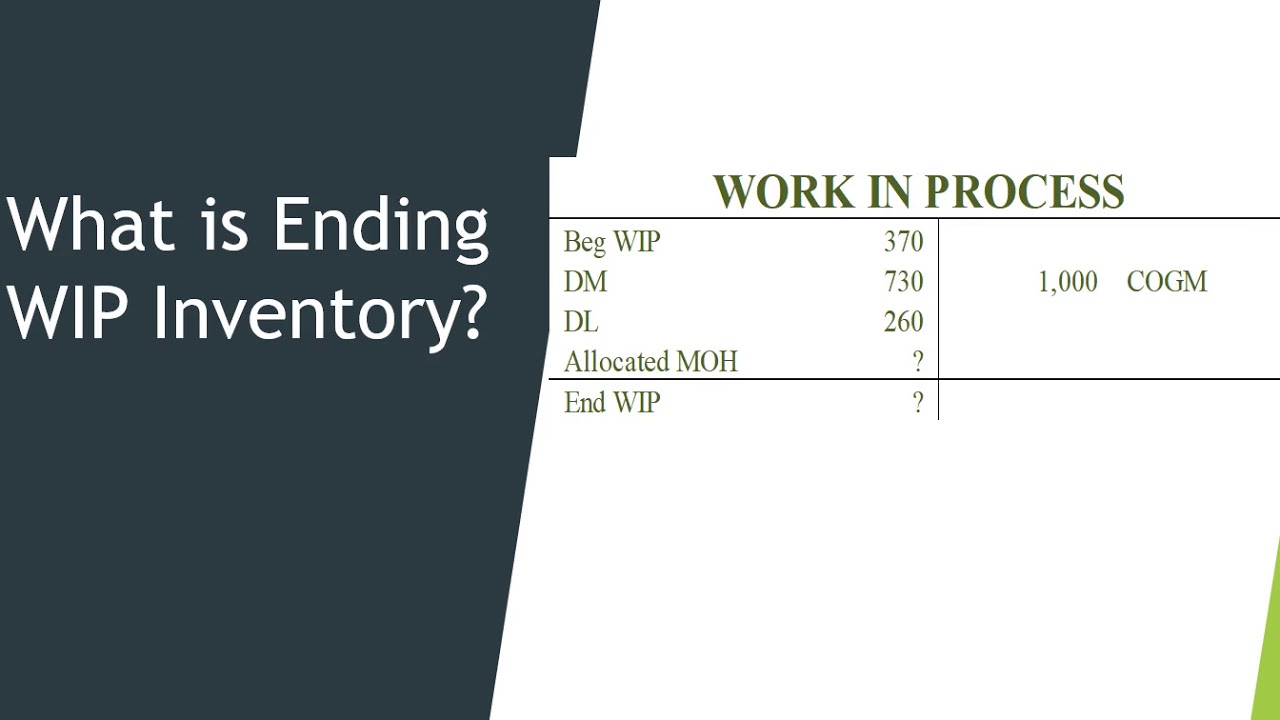

WIP inventory includes the cost of raw. Abnormal loss- Physical units produced are multiplied by the degree of completion. The amount of ending work in process must be derived as part of the period-end closing process and is also useful for tracking the volume of production activity.

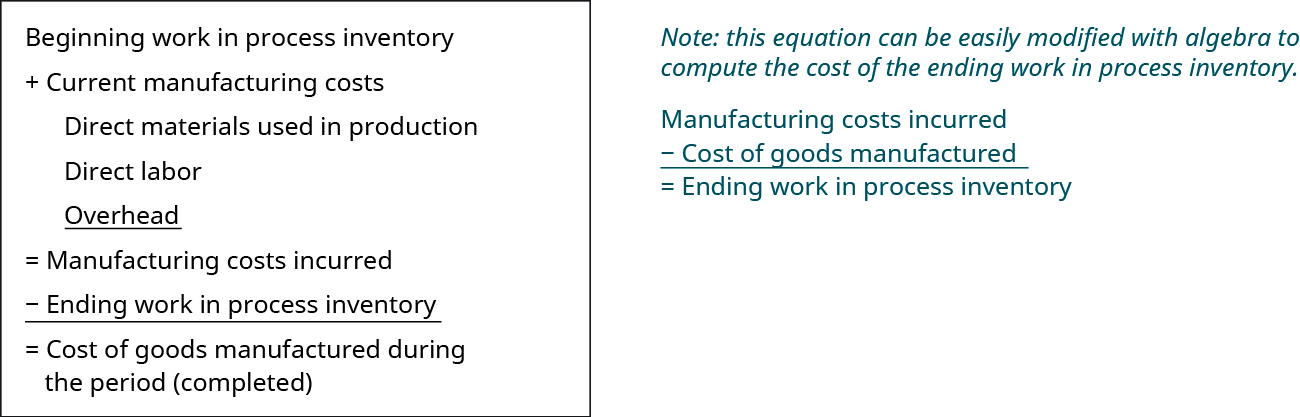

Unlike just manufacturing costs the cost of manufactured costs is the entirety of costs incurred in making a final product. Work in progress WIP sometimes referred to as work in process is the sum of all costs put into the production process to manufacture products that. Time and Money Saved.

WIP is calculated as a sum of WIP inventory total direct labor costs and. As opposed to work in process inventory which calculates short-term completion costs for items that require additional production work in progress inventory is a long-term. As determined by previous accounting records your companys beginning WIP is 115000.

Work in process is a crucial stage in the production process where a manufacturer converts raw materials into finished items. Ad Track every stock move from purchase to warehouse bin to sales order. Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs - Cost of Finished Goods.

Work in process inventory refers to materials that are waiting to be assembled and sold. The calculation to find the work-in-progress inventory at the end of the year is as follows. WIP inventory is a component of the inventory asset on the companys balance sheet.

On the other hand work in. Work In Progress - WIP. During the year 150000 is spent on manufacturing.

Abnormal gain- Physical units 100 complete. The business needs to maintain an accurate record. On the other hand work in progress is often used in construction and other service businesses and refers to the progress.

COGM is important because its the last element youll. This calculation typically includes the cost of raw materials being used. Suppose the XYZ widget company has an initial WIP inventory of 10000 for the year.

The work in process formula is. During the span of the time the company incurs manufacturing costs of. Ad Choose Your Inventory Tools from the Premier Resource for Businesses.

Get the Inventory Tools your competitors are already using - Start Now. How to Calculate Ending Work In Process Inventory. Beginning work-in-progress inventory 2856000.

Understanding How Wip Work In Progress Is Calculated In Sap With Example Tech Concept Hub

3 Types Of Inventory Raw Materials Wip And Finished Goods Youtube

Wip Inventory Definition Examples Of Work In Progress Inventory

Work In Progress Meaning Importance Accounting And More

What Is Work In Process Wip Inventory How To Calculate It Ware2go

Work In Progress Wip Definition Example Finance Strategists

Work In Process Wip Inventory Youtube

What Is A Work In Progress Wip 2020 Robinhood

Work In Process Inventory Formula Wip Inventory Definition

Ending Work In Process Double Entry Bookkeeping

How To Calculate Manufacturing Work In Progress Wip Solutionbuggy

What Is Inventory Turnover Inventory Turnover Formula In 3 Steps

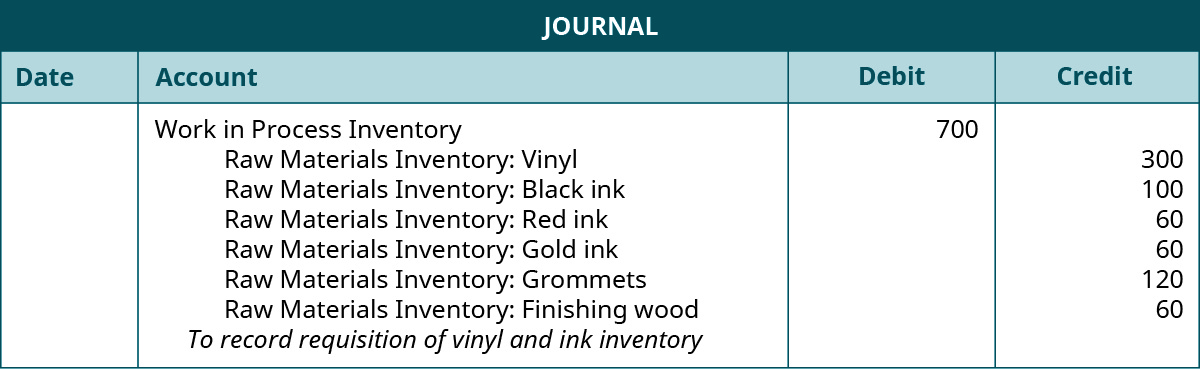

Prepare Journal Entries For A Job Order Cost System Principles Of Accounting Volume 2 Managerial Accounting

Use The Job Order Costing Method To Trace The Flow Of Product Costs Through The Inventory Accounts Principles Of Accounting Volume 2 Managerial Accounting

How To Calculate Finished Goods Inventory

Cost Of Goods Manufactured Formula Examples With Excel Template